Research labs are the most technically sophisticated architecture that our society creates. Architectural challenge in designing a laboratory is as demanding as the technical challenge associated with it. Labs today exemplify in function, style, structure, scientific capability as well as socio-cultural aspect of place. The most productive and successful scientists are intimately familiar with both the substance and style of each other’s work. They are quick in adapting to the new research approaches and tools that become available. Also experiences a scientist carries while working in different organizations and also across continents makes them believe in a new outlook and want for new, practical and more productive infrastructure.

Exceptional facilities don’t just happen- they are planned to be functional, efficient, cost effective and compliant to all regulations. They are planned to meet: researchers’ requirements, complete adherence to safety norms, synergy with outside environment, right ambience for employees to flourish and also built to last with appealing architecture.

1.0 LAB FACILITIES- INTRODUCTION

Labs are required mostly in following sectors:

| Pharmaceutical based labs | Food processing | Animal Research labs |

| Chemical Labs | Petroleum products | Clinical research labs |

| Engineering labs | Material standards Bureau |

1.1 Types of labs (Pharma sector):

- Formulation Development (FD)

- Process Chemistry (PC)

- Analytical Development

- Analytical support labs for FD & PC

- Kilo lab / Scale-up lab

- Pilot plant

2.0 PROCESS OF LAB DESIGN & ENGINEERING:

- Understanding User Requirement Specifications from Client

- Identifying the appropriate design concerns for the particular project

- Earmarking Design Approach

- Finalising Lab module after discussing with client

- Preparing conceptual co-relation diagrams

- Planning Philosophy – Drawing preparation

- Interface with engineering team for their inputs

- Specifications for lab-furniture

Final layouts are prepared subsequently, coordinated with various agencies. Tendering of various works is done simultaneously. Implementation & site works becomes quite simple once all the design and engineering aspects are well coordinated/engineered at desk level itself.

Each process is briefly described below.

2.1 a General requirements for Process Chemistry

-

-

- No. of labs

- Fume hoods in each lab – bench type or walk-in

- Work counters- island tables

- Wet benches

- Dry benches (the length of table depends on no. of people working in a lab and also the equipment identified for a particular lab.)

-

-

-

- Equipment list / instruments

- Scientist sitting capacities for each lab

- Preferred segregation of equipment/instrument room wise

- Storage requirements

-

2.1b General URS for Formulation Development Labs

-

-

- Dosage form

-

-

-

- OSD

- Liquid

- Sterile LVP or SVP

- Ointment

- High potent / ONCO

- Hormone

- Neutraceutical

- In terms of suites – no. of suites

- Analytical support and pre-formulations

- Pilot plant

-

2.2 Identifying the appropriate design concerns for the particular project

- Architectural Layouts & Design concerns

- Functional-Comfort and Convenience

- Operational Convenience

- Regulatory Requirements

- Safety

- Engineering, Utility & Services

- Efficiency in Space planning

- Ergonomics

- Modularity and expandability

- Aesthetics

- Site Specific potentials and constraints

- Sustainability

- Maintenance

- Economy

- Energy Efficiency

- GMP/GLP & Process Hygiene

2.3 Earmarking Design Approach

Functionality, space, safety, and flexibility are the four most desired characteristics of a facility. These four characteristics are interconnected in laboratory design; changing one of these features affects the others. While functionality and safety are never compromised, space and flexibility may be sacrificed due to budget constraints.

| SPACE PLANNING | SERVICES AND UTILITY MANAGEMENT AND INTEGRITY | WORK AMBIENCE |

|

|

|

2.4 Finalising Design Module

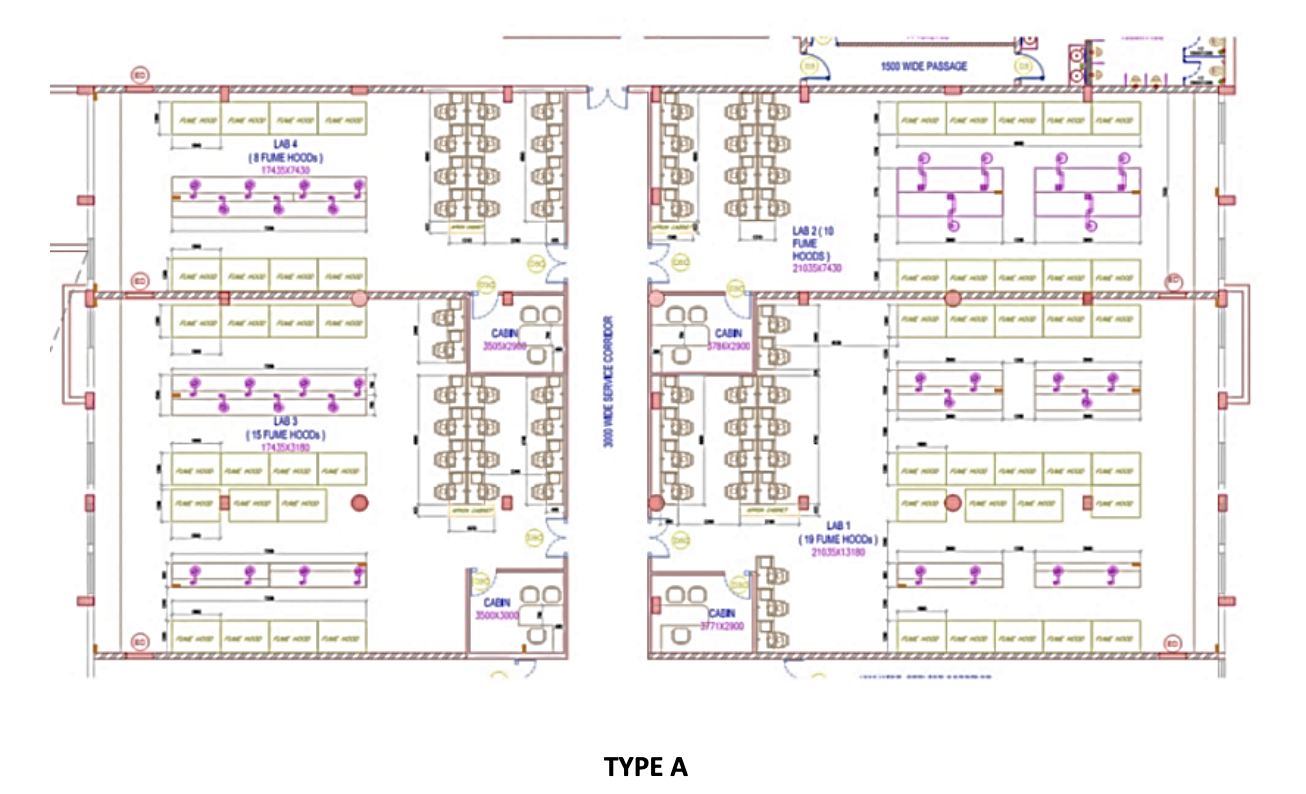

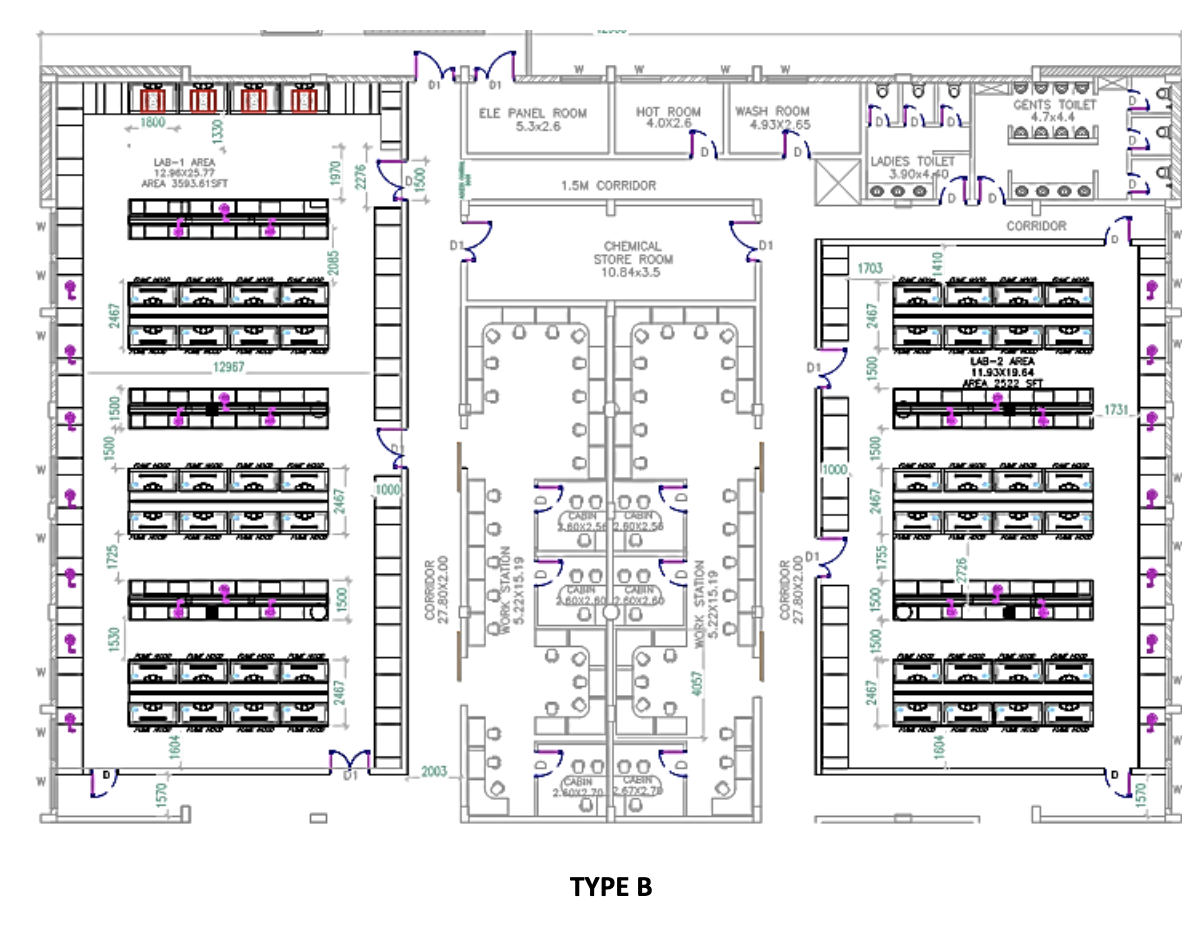

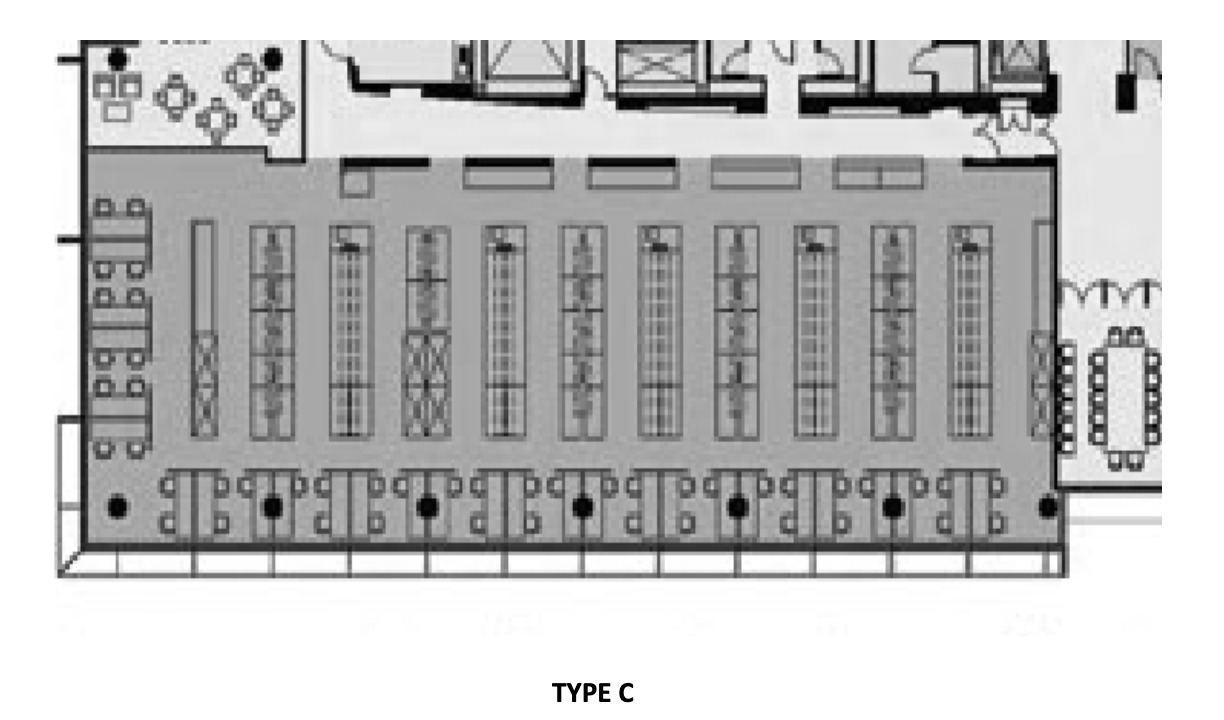

This is the most important aspect of lab- finalising the lab module based on client interaction. Few of the lab modules are depicted in the following sketches:

Type A is a typical process lab where scientist sitting area alongwith the group leader is assigned particularly for a lab. Here the scientist requirement is calculated based on the fumehood no. and space is allocated for the team and team leader along with the lab. Generally this type of labs are designed for contract manufacturing or dedicated work flow teams( in chemical industry they need specific labs for safety, effluent, characterisation, chlorination, etc)

Type B is a lab where the scientist pool is allocated a common central space and all labs are located around it. There is generally a corridor in-between labs and scientist sitting area. These types of labs are particularly designed where all the labs are working on same product and there is no need of any secrecy in documentation area. The scientists however are given access cards for entering the labs.

Type C is an open lab concept where all the fume hoods along with dry and wet benches are located together. Lab scientists are also located in the same vicinity near the external walls for light ventilation. These type of labs are generally seen in universities but are also popular as a typical standardised layout for many companies.

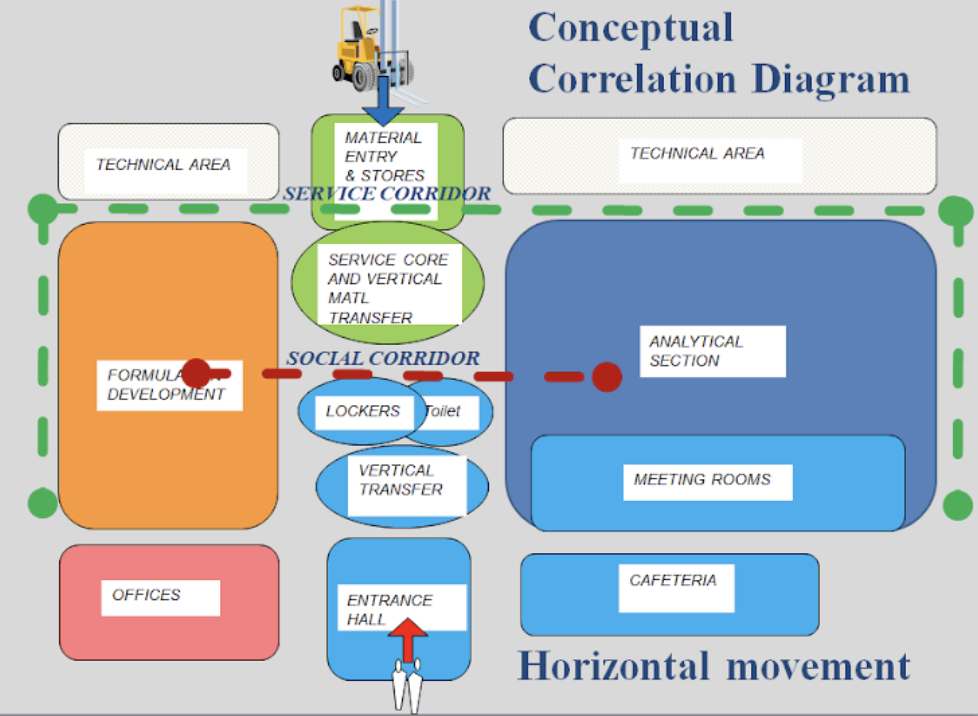

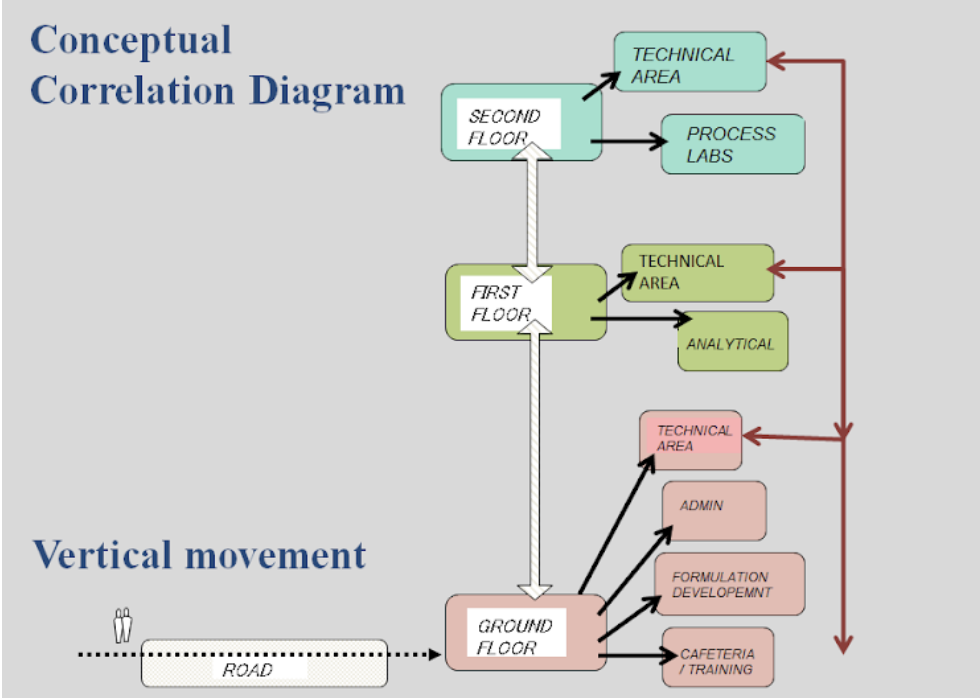

2.5 Conceptual Co-relation diagrams

Once the module for process labs is finalised the co-relation diagram is worked by the Architect to understand the internal movements horizontally as well as vertically in the building.

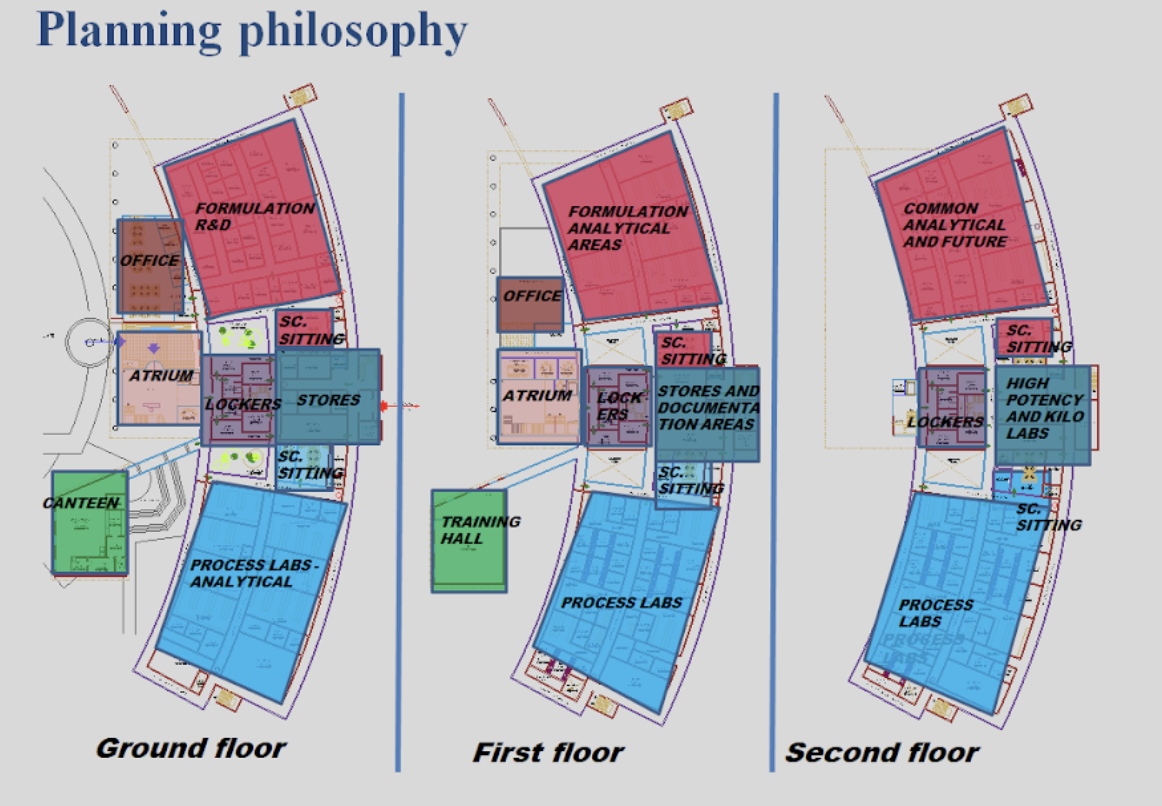

2.6 Planning Philosophy

Once the co-relation diagram is finalised, the overall planning philosophy is put in place the diagram gets developed into a working layout. The labs, corridors, stores, change rooms, technical areas, etc are integrated. The service and social corridor based on man-material flow is worked out and assimilated with the layout.

Sections are also developed simultaneously to understand the man-material and utility lines routing through the designed space.

2.7 Interface with engineering team for design inputs

Floor drawings and sections are further circulated to the respective Engineering disciplines for further integration of electrical, HVAC, mechanical layouts.

Electrical aspects will consist of the following:

- Transformer

- HT Breaker & Switch Yard

- Switch gear panels, PCC, MCC

- Power distribution

- Lighting distribution

- Cables & Cable racks

- UPS

- DG

Along with this special indoor/outdoor light fittings & fixtures would be selected to match the overall ambience of the lab building.

HVAC aspects will consist of the following:

- AHUs

- Chillers

- De-humidifiers

- Scrubbers

- Condensed water

- Ducting

- BMS for controlling the parameters

Mechanical aspects will consist of the following:

- Chilled water

- Boiler

- Centralised Vacuum system

- Compressors

- Industrial gases- Hydrogen, Helium, Argon, Oxygen, LPG, CO2 – Gas bank and distribution

- Water treatment Plant

- Process Air

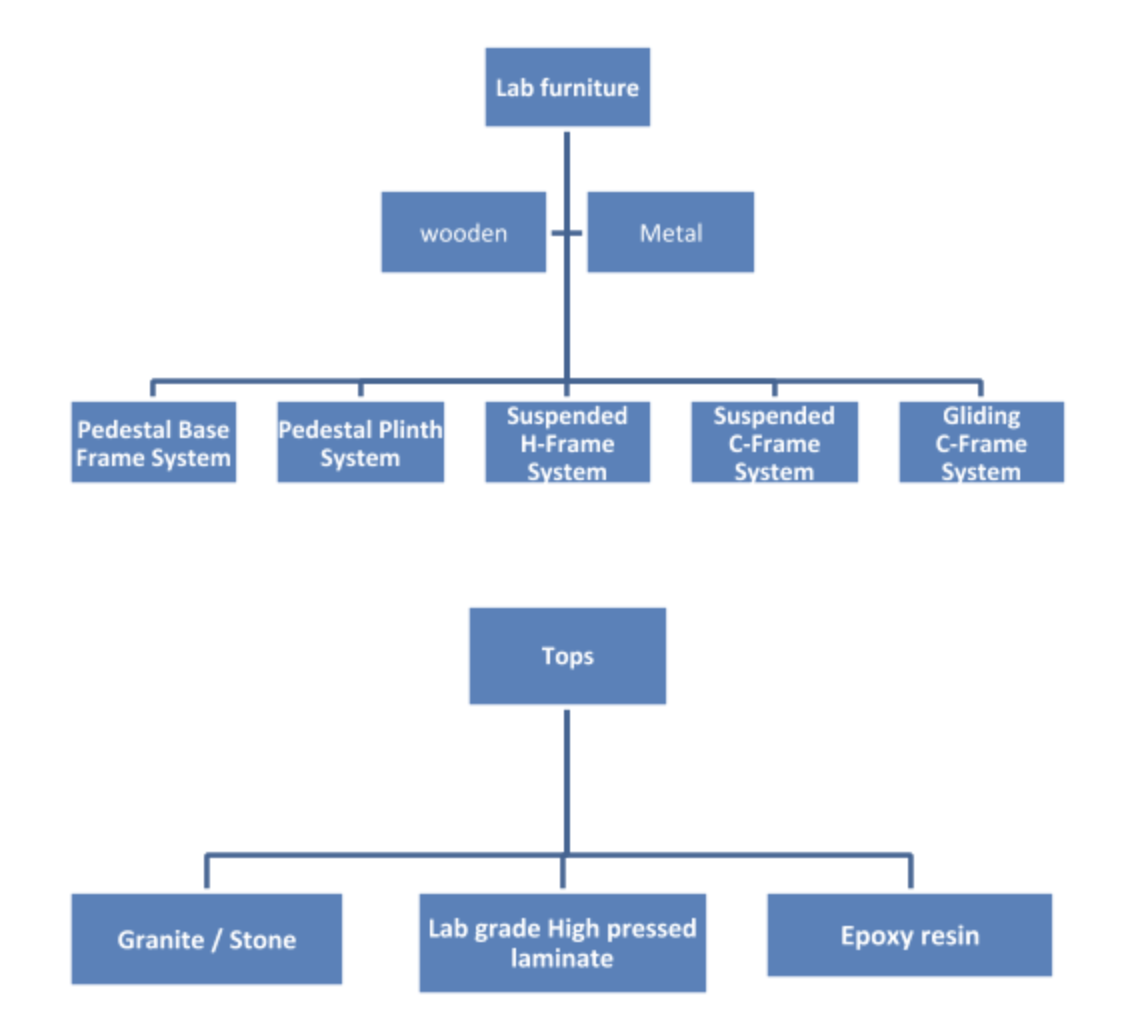

2.8 Lab Furniture Specifications and overall Interior working space strategy

Simultaneously lab furniture specification items are finalised and various tenders are floated for procurement process.

Types of partition:

Partition type-1

1200mm high brick work with plaster and paint + 100mm thick toughened glass fixed with fittings

| PROS: | CONS: |

| More openness in the facility due to glass fixed with patch fittings | Painted surfaces need more maintenance.

Brick work/plaster/painting/granite sill/skirting works consumes more time. |

Partition type-2

Pre-coated GI sheets with rock wool infill and vision panels and epoxy coving

| PROS: | CONS: |

| Modular- most of the detailing done in office and ready to install panels are sent to site

Good and clean appearance due to precoated factory made panels. Easy to maintain Installation work is clean and fast at site. |

Design has to be perfect and well developed in advance with complete coordination. Later changes are difficult. |

3.0 STRATEGIES TO BUILD FLEXIBLE, COLLABORATIVE RESEARCH ENVIRONMENTS INCLUDE:

- The use of Furniture systems that are easily moveable

- Limiting fixed elements in the laboratories

- Containing hazards in the smallest workable area.

- Movable and height-adjustable laboratory benches with only minimal services are the norm in the interior of laboratories.

- Piped services (such as water, natural gas, and vacuum) serve perimeter benches only

- Lab air requirements arise from the need to exhaust dangerous fumes, as well as the need to maintain safety and comfort, given general lab activity and heat-generating equipment like freezers, pumps, and spectrometers.

- Occupancy sensors on fume hoods can reduce airflow when the laboratory is unoccupied

- Isolating chemical fume hoods in alcoves reduces the overall volume of air required for safe operation.

- Uses of air sensing technologies – either setting lower baseline air change rates or recirculate exhaust air.

- Specifying only as many hoods as are absolutely necessary and educating workers to keep sashes closed whenever possible

4.0 SUSTAINABLE DESIGN OF LABS

…a building “that meets the need of contemporary society without denying future generations of the ability to meet their needs….

(Definition of sustainable architecture offered by the UNCED Bruntland Commission)

Research labs are some of the most resource-intensive. They use enormous amount of energy to cool, heat and power the lab equipment, most of which are sophisticated. Large volume of exhaust air is emitted. Finding ways to design and engineer research laboratories more efficiently, effectively and sustainably is the need of hour. Part of this concern is the ultimate awareness of the external environmental issues caused by the building and how it architecturally relates not only to the local but also to the global environment. The key to successful implementation of this concept again comes back to sustainable design.

Improvements to building design will continue to evolve over time. Building and scientific equipment vendors must push current boundaries for energy efficient equipment; educational systems at all levels must continue to promote and expand environmental awareness. Now is the time to aggressively implement strategies to lessen future environmental impact and respond to new directions in research; we need to design tomorrow’s laboratories today.

This article is an objective to generate continued discussion and document strategies to an organised way to build a lab with best practices and sustainable design approach.

Courtsey – Ar. Monali S. Pednekar, DGM-Architecture, Knexir Consultants Pvt. Ltd.