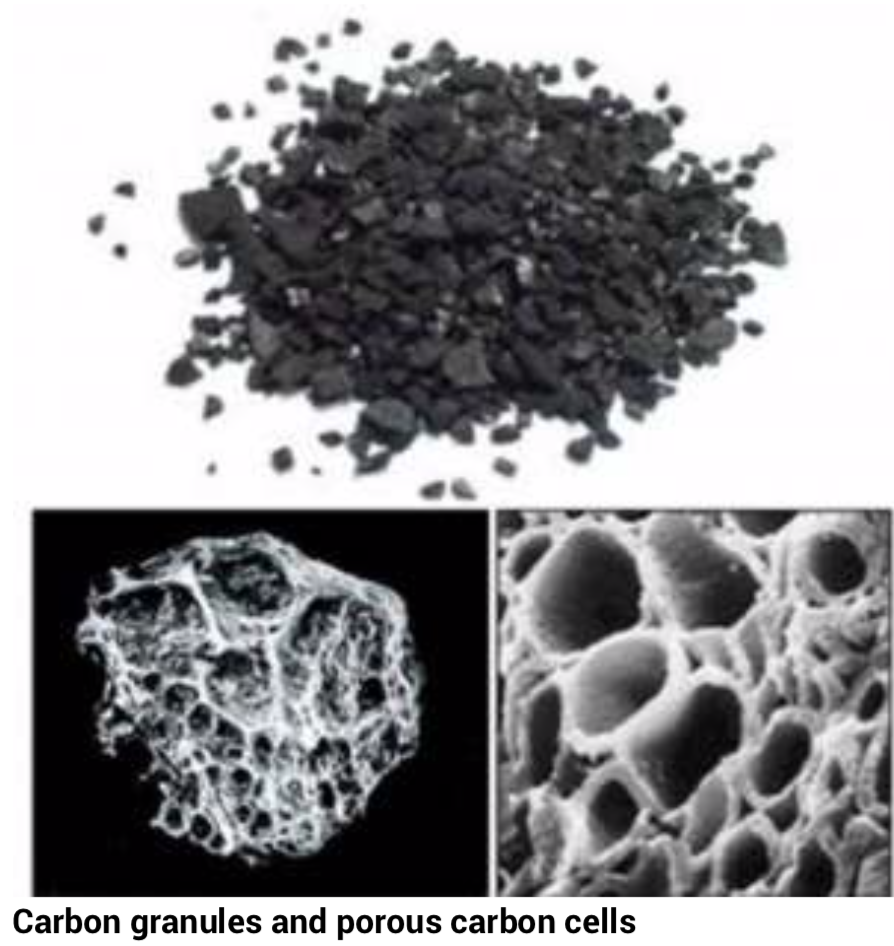

Carbon filtration is used to remove smells and vapours from chemicals. Coconut shells are used as base carbon which is heated to temperatures up to 650°C until the shell is carbonised. The carbon can be granular or in pellet forms. Please see the picture below.

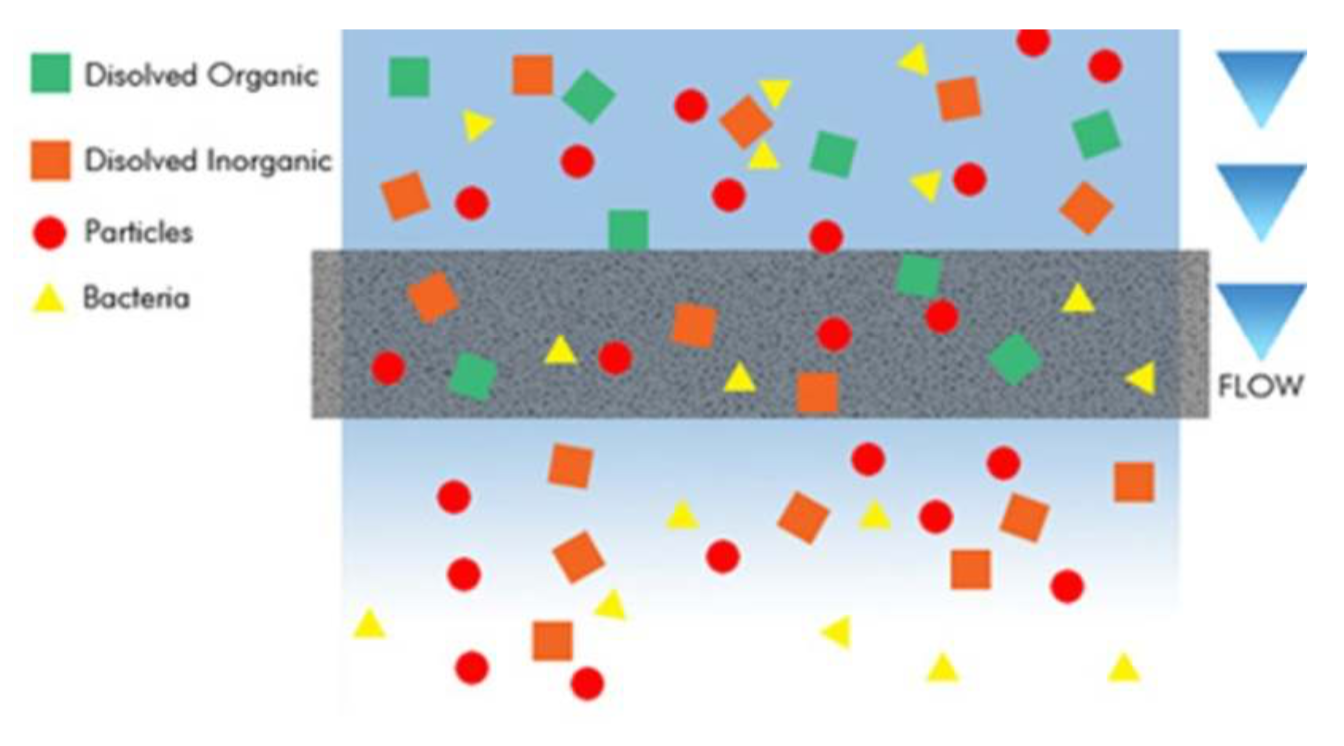

The carbon medium is dosed with specially selected chemical mixtures to ensure a high efficiency through the filters life. By dosing the carbon medium the filters become positively charged to attract the selected chemicals, this reaction is called adsorption. The chemicals to be removed in the process are attracted to the nanopores of the carbon and are held in suspension (filling the holes). The chemicals do not absorb (soak into the carbon).

The design criteria are 0.2m/s through the carbon filter medium if this value is increased then the efficiency is decreased. If the airflow is increased too high then the chemicals can be blown out of the filter back into the environment.

Retention capacity

The retention capacity depends upon the weight of the chemicals it can absorb. This will effect with the size and layers of filters. More the retention capacity we need, bigger will be the filter sizes, based upon the weight and size of the filter. Depending on the weight, the filters are categorised as below:

F4 filter cell 7Kg – 9KG

F3 filter cell 5Kg – 7KG

The medium used as dosing also plays a vital role in weight of the filters.

What is carbon Filtration?

Carbon filtration is used to remove unwanted smells and vapours from the atmosphere. A filter medium in pellet form (coconut shell) is treated at high temperature and then dosed with chemicals to enable the carbon to attract the chemical to be removed. A carbon filter will not remove particulates or bacteria. Please see activated carbon medium and carbon adsorption below.

Example of an Organic Solvent (OS) filter

A single cell filter can adsorb up to 2000g, more in some cases, of chemical before saturating. The filters do not block like a particulate filter, the filters are chemically charged (dosed with chemicals to suit the chemical to be removed) to attract the chemical as the air vapour passes through the filter medium (Super-heated coconut shell). The filter will adsorb the chemical by filling the micro/ nano holes (see activated carbon medium) until the filter cannot hold anymore chemical before the

vapour is present back into the room. For example if we use an OS filter for Acetone and the recommended value is 450g, this means that the weight of the filter will increase by this value. Please see the pictures above.

Test method

Under regulations, fume hoods require be serviced every 14 months. The cabinets are tested annually to comply to European and USA standards for airflow check and filter integrity. In this case the primary carbon filter is tested by a Gastec technique. A known solvent is kept inside the cabinet, with the unit switched on. The Gastec pump and glass vial indicator are placed on the exhaust of the cabinet (after the filter). Air is drawn thru the indicator vial by drawing air (vacuum) from the exhaust stream, the compound within the vial will react with any chemical passing and thus will indicate a change in colour (pH compound) which can be read off on a graduated scale reading in PPM. The values for acceptance will depend upon the local environmental legislation. As in the USA and Europe, there are specifications for airborne vapour in the atmosphere.

Courtesy: Bigneat Ltd, UK